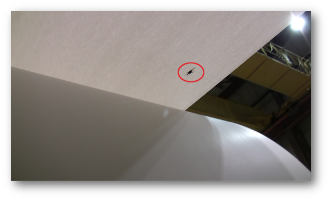

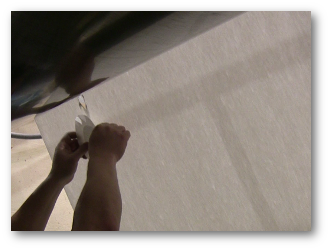

LSZ's Stop on Defect system is an effective tool to trigger a winder slow/stop to allow for paper patching or splicing. High accuracy is assured by utilizing LSZ's high-speed diameter and caliper processors.

An interface to a mill supplied actionable defect signal is fed into the LSZ Stop on Defect system. Defects are tracked by spool using RFID technology through the reeling and unwinding process. The winder is signalled to decelerate to a pre-defined patch speed in advance of the defect.

Features & Benefits

| Feature | Benefit |

|---|---|

| Display of wound-in caliper/density | Reduces the potential of crepe wrinkles from reeling and shipping deformation of rolls. |

| Optional display of key winding parameters | Winding parameters such as torque, nip and tension can be overlaid on wound-in density profiles. |

| Profile archiving | Rapid review of historical profiles sorted by grade or time. Profiles can be overlaid to help visualize anomalies. |

| Optional setpoint control | Grade and diameter dependent setpoint control allows maximum flexibility of torque, nip and tension control. Operators can bias or override control curves (optional). |

More Information

Contact LSZ for more information about our effective and winder stopping technologies.