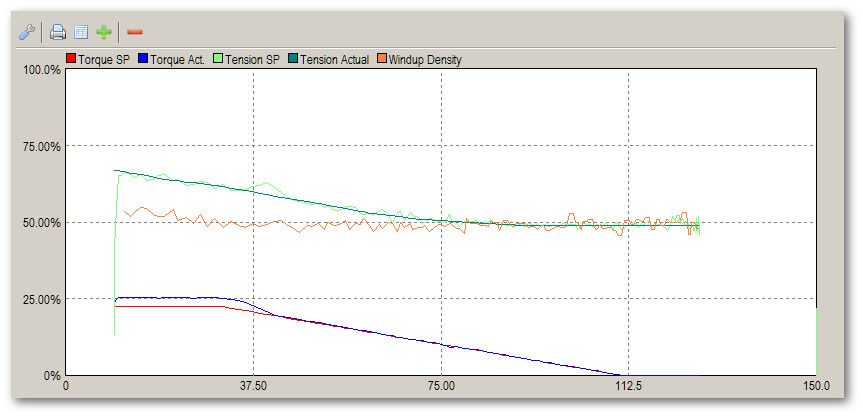

The LSZ Roll Density Monitor (RDM) provide a clear visual indication of roll/reel structure. Key winding parameters like torque, rider roll load and web tension can be overlaid on wound-in caliper/density as added diagnostic information.

This tool enables operators to visualize potential roll structure problems before rolls leave the winder.

The RDM can be combined with the LSZ Roll Density Controller (RDC) to provide setpoint control of torque, nip and tension. Control curves are defined by grade and diameter and automatically selected as reels are loaded into the winder. Control curves can be overridden or biased by the operator.

Features & Benefits

| Feature | Benefit |

|---|---|

| Display of wound-in caliper/density | Reduces the potential of crepe wrinkles from reeling and shipping deformation of rolls. |

| Optional display of key winding parameters | Winding parameters such as torque, nip and tension can be overlaid on wound-in density profiles. |

| Profile archiving | Rapid review of historical profiles sorted by grade or time. Profiles can be overlaid to help visualize anomalies. |

| Optional setpoint control | Grade and diameter dependent setpoint control allows maximum flexibility of torque, nip and tension control. Operators can bias or override control curves (optional). |

More Information

Contact LSZ to see how visibility on roll structure can be easily added to existing winding processes.